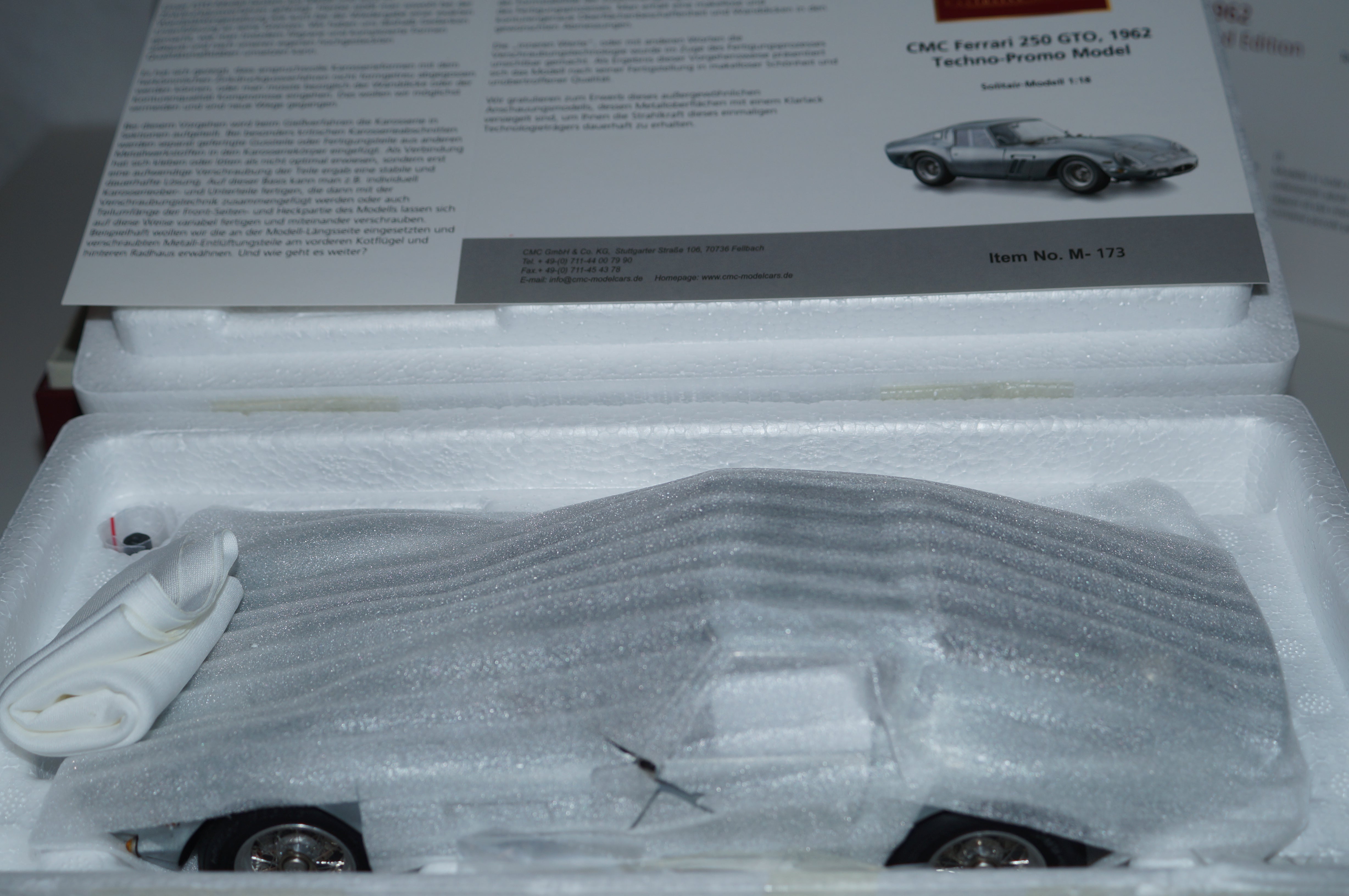

CMC Ferrari 250 GTO Techno Promo Model CMC M-173 LE 500

Description

Our GTO model is made of metal and manufactured using the zinc die-casting process. This approach poses limitations both in terms of wall thickness and the reproduction of precise lines. Therefore, we considered how to adequately implement delicate and complex shapes while maintaining our own high quality standards.

It has been shown that complex body shapes cannot be accurately cast using the conventional zinc die-casting process, or compromises would be required regarding wall thickness or contour quality. We want to avoid this wherever possible and have taken new approaches.

In this process, the body is divided into sections during the casting process. For particularly critical body sections, separately manufactured cast parts or parts made of other metal materials are inserted into the body. Gluing or soldering have proven to be less than optimal as a connection; instead, only complex screwing of the parts results in a stable and durable solution. On this basis, for example, individual upper and lower body sections can be manufactured, which are then joined together using screwing technology. Even parts of the front, sides, and rear sections of the model can be variably manufactured and screwed together in this way. As an example, we would like to mention the metal ventilation parts on the front fender and rear wheel arch, which are inserted and screwed onto the long side of the model. And what happens next?

After the individual parts have been joined or inserted, any resulting joint gaps, gaps left by screw heads, or remaining threads are filled with a special filler and then carefully sanded and polished. A dimensional stability test of the joined parts concludes this part of the manufacturing process. This results in a flawless and precisely contoured surface finish and wall thicknesses in the desired dimensions.

The "inner values," or in other words, the screw-connection technology, were rendered invisible during the manufacturing process. As a result of this approach, the model presents itself with flawless beauty and unsurpassed quality upon completion.

We congratulate you on the purchase of this extraordinary demonstration model, whose metal surfaces are sealed with a clear varnish in order to permanently preserve the radiance of this unique technology carrier.

CMC Legal Disclaimer

The use of racing team and/or driver names, symbols, starting numbers, and/or descriptions is solely for reference purposes. Unless otherwise stated, it does not imply that the CMC scale model is a product of any of these racing teams/drivers or endorsed by any of them.

Technical data of the original vehicle

•Two-seater, aluminum coupé body (Berlinetta) on a tubular frame with side tubular frame reinforcement

•Twelve-cylinder V-engine with 60° cylinder angle and two overhead camshafts

•Bore x Stroke: 73 x 58.8mm

•Displacement: 2,953 cc

•Compression: 9.8:1

•Power: 300 hp at 7,500 rpm

•Maximum speed: approx. 280km/h

•Mixture preparation: Six Weber 38 DCN twin carburettors

•Dry sump lubrication

•Transmission: Synchronized five-speed manual transmission with rear-wheel drive

•Chassis: Front independent suspension on trapezoidal wishbones with coil springs; rear rigid axle with longitudinal leaf springs and Koni shock absorbers as well as Watt linkage

•Brakes: Disc brakes all around

•Wheelbase: 2,400 mm

•Track width front/rear: 1,354 (1,351) / 1,350 (1,346) mm

•Vehicle length / width / height: 4,325 / 1,600 / 1,210 mm

•Weight ready to drive: approx. 900 kg

•Construction period / number of units: 1962-1964 / 36 units + 3 units with four-liter engine

Special feature: 3 lockable covers above the radiator grille close additional air intakes, which can be removed if necessary.

Notice

Our GTO model is made of metal and manufactured using the zinc die-casting process. This approach poses limitations both in terms of wall thickness and the reproduction of precise lines. Therefore, we considered how to adequately implement delicate and complex shapes while maintaining our own high quality standards.

It has been shown that complex body shapes cannot be accurately cast using the conventional zinc die-casting process, or compromises would be required regarding wall thickness or contour quality. We want to avoid this wherever possible and have taken new approaches.

In this process, the body is divided into sections during the casting process. For particularly critical body sections, separately manufactured cast parts or parts made of other metal materials are inserted into the body. Gluing or soldering have proven to be less than optimal as a connection; instead, only complex screwing of the parts results in a stable and durable solution. On this basis, for example, individual upper and lower body sections can be manufactured, which are then joined together using screwing technology. Even parts of the front, sides, and rear sections of the model can be variably manufactured and screwed together in this way. As an example, we would like to mention the metal ventilation parts on the front fender and rear wheel arch, which are inserted and screwed onto the long side of the model. And what happens next?

After the individual parts have been joined or inserted, any resulting joint gaps, gaps left by screw heads, or remaining threads are filled with a special filler and then carefully sanded and polished. A dimensional stability test of the joined parts concludes this part of the manufacturing process. This results in a flawless and precisely contoured surface finish and wall thicknesses in the desired dimensions.

The "inner values," or in other words, the screw-connection technology, were rendered invisible during the manufacturing process. As a result of this approach, the model presents itself with flawless beauty and unsurpassed quality upon completion.

We congratulate you on the purchase of this extraordinary demonstration model, whose metal surfaces are sealed with a clear varnish in order to permanently preserve the radiance of this unique technology carrier.

CMC Legal Disclaimer

The use of racing team and/or driver names, symbols, starting numbers, and/or descriptions is solely for reference purposes. Unless otherwise stated, it does not imply that the CMC scale model is a product of any of these racing teams/drivers or endorsed by any of them.

Technical data of the original vehicle

•Two-seater, aluminum coupé body (Berlinetta) on a tubular frame with side tubular frame reinforcement

•Twelve-cylinder V-engine with 60° cylinder angle and two overhead camshafts

•Bore x Stroke: 73 x 58.8mm

•Displacement: 2,953 cc

•Compression: 9.8:1

•Power: 300 hp at 7,500 rpm

•Maximum speed: approx. 280km/h

•Mixture preparation: Six Weber 38 DCN twin carburettors

•Dry sump lubrication

•Transmission: Synchronized five-speed manual transmission with rear-wheel drive

•Chassis: Front independent suspension on trapezoidal wishbones with coil springs; rear rigid axle with longitudinal leaf springs and Koni shock absorbers as well as Watt linkage

•Brakes: Disc brakes all around

•Wheelbase: 2,400 mm

•Track width front/rear: 1,354 (1,351) / 1,350 (1,346) mm

•Vehicle length / width / height: 4,325 / 1,600 / 1,210 mm

•Weight ready to drive: approx. 900 kg

•Construction period / number of units: 1962-1964 / 36 units + 3 units with four-liter engine

Special feature: 3 lockable covers above the radiator grille close additional air intakes, which can be removed if necessary.